2.1 Rolling Stock Design Liaison Meeting for Shanghai Metro Line 2 (1997)

SYSTRA assisted the client to review the detailed design completed by rolling stock supplier, and attended the design liaison meetings.

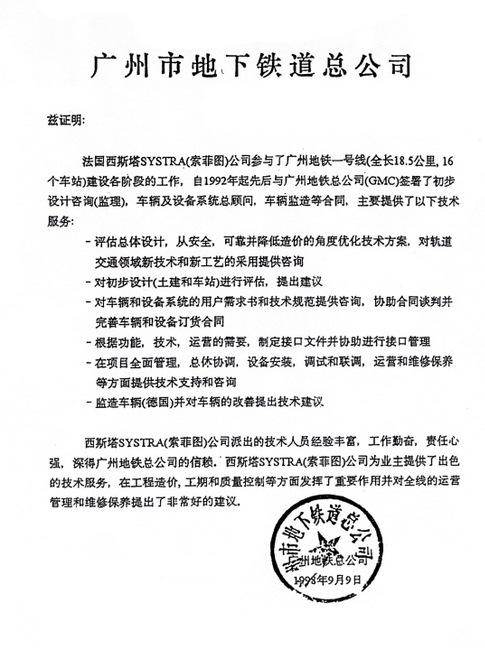

2.2 Rolling Stock Manufacture Supervision for Guangzhou Metro Line 1 (1997-1999)

In order to ensure the rolling stock manufacturing quality of German ADTRANZ, the client entrusted SYSTRA to undertake the task of manufacture supervision. Since 1997, SYSTRA finished supervising the manufacture of 21 trains, which has been appreciated by Guangzhou Metro Corporation.

2.3 Passenger Railway Rolling Stock Manufacture Supervision (2001-2002)

SYSTRA was responsible for supervising the manufacture of passenger railway rolling stock for Qingdao Sifang factory in BOMBARDIER France.

2.4 Shanghai Urban Railway Pearl Line Phase I (2000-2004)

SYSTRA participated in the design review of rolling stock of Shanghai Metro Pearl Line Phase I, and was responsible for the supervision of all the trains of the line. Firstly SYSTRA finished the supervision of the construction of ALSTOM's first and second trains in France, and then the construction of other trains in Puzhen, which were totally 28 trains.

2.5 Rolling stock Manufacture Supervision for Guangzhou Metro Line 2 (2002-2004)

SYSTRA attended the design liaison meeting held in Germany, participated in First Article Inspection and the supervision of some trains in Changchun.

2.6 Rolling stock Manufacture Supervision for Nanjing Metro South-North Line Phase I (2004-2006)

SYSTRA was entrusted by Nanjing Metro Company to provide technical consultation on major technical problems occurred in the manufacturing process of No. 3-20 trains, and provide supervision service for train assembly, debugging, test and acceptance.

2.7 Technical Consultation on Rolling Stock Design and Manufacture in Nanjing Puzhen (2006-2010)

SYSTRA assisted Puzhen Rolling Stock Factory in the design, technology and quality control of railway transport rolling stock.

2.8 Quality Assurance and Technical Support for Rolling Stock Component Manufacture in Nanjing Puzhen (2010-2012)

SYSTRA analyzed the problems in the organization and management of rolling stock supervision and component manufacturing. The component manufacturing quality is dynamically optimized by monitoring and applying the combination of active and passive quality control model and causal analysis, in order to ensure the progress and quality of rolling stock supervision, and provide reference for the follow-up work of supervision.

2.9 Platform Screen Door Manufacture Quality Control and First Article Inspection for Santiago Metro in Chili (2015)

SYSTRA provided quality control services on behalf of the client in the process of product design, processing, testing, debugging and acceptance carried out by the platform screen door supplier in Shanghai.